We’ve received lots of questions about our engine, but there are two questions that are asked most frequently. We've taken this opportunity to answer these two questions here with an aim to provide as much information and transparency as we can to our customers.

The two most common questions posed to us about our engine are:

- What is the anticipated price for the engine?

- What is the projected performance of the engine? (Power available and fuel flows)

What is the anticipated price for the engine?

Short answer – Our target is US$80,000 - $85,000 for the base engine including accessories to run it (FADEC, fuel pumps, oil pump, starter/generator etc.) but this price does not include a propeller.

Long answer – Components for the first engine are currently being either manufactured or sourced. Typically, prototype engines cost an order of magnitude more than a production engine due to the set-up/non-recurring engineering costs and the lack of ability to obtain cost savings associated with volume production. Manufacturers charge a premium to fit a one-off into their production schedule and to get the part made in a timely manner, and they are not able to offer the material cost-benefit that is derived from bulk orders of materials.

Another factor to consider at this early stage when predicting a cost is that the company that is manufacturing a one-off prototype component may not be the same company that supplies production components.

As with any engine development program, the physical/technical differences between the first engine and the production engine can be significant, as much as we’d like to think we could get it right the first time. Consequently, determining a cost for a production component that may change from its current form is also difficult.

Another factor at the moment, is around the global supply chain issues. The availability and cost of the materials that constitute our engine are fluctuating significantly with some materials now costing three times what they cost 18 months ago. If prices stay high or material availability becomes an issue such that redesign work is required to offer alternative materials, this will affect the price point for our engine.

The bottom line is that while we have a target price point for the engine and current indications are that this price point can be achieved, there are still many variables and unknowns that will affect the final cost of the engine. Our no-cost, no-obligation Registration of Interest program addresses this issue by ensuring that our potential customers do not hold any risk until there is certainty around performance, specifications, delivery timeframe and delivery cost.

What is the projected performance of the engine?

We need to be very clear that the engine has not yet run and any figures that we publish are theoretical. That said, the software tools that we are using to predict the performance of gas turbine engines are well proven to be accurate so we have a high degree of confidence that, assuming we have designed the engine properly, it should perform closely to the predicted specifications. Check out this video from Leap Australia about our use of their simulation product, Ansys.

Of course, it is the actual performance to be achieved by the engine that will determine whether this engine will suit our customers’ needs.

The Talon engine is unique amongst the current 200hp aero engines in that it will be a recuperated turboprop engine. The Recuperator component should allow the engine to offer better fuel efficiency than a traditional non-recuperated gas turbine aero engine. Consequently, the Recuperator is one of the most important components of the Talon.

In selecting and finalizing the design of the Recuperator, there was a design decision made based on a trade-off between the following factors:

- Size – it needs to be compact for an aero engine application

- Weight – it needs to be as light as possible for an aero application

- Performance – it needs to be able to substantially improve the fuel efficiency of the engine

- Manufacturability – can it be built in the form that it is designed?

- Cost – it needs to be affordable.

We needed to make a judgement call on what would be the most important features for our future customers knowing that different customers would have different priorities.

As a company, we have made those design decisions, based on what we think is the best compromise of all the factors under consideration to ensure that this engine will be the most appealing to the broadest customer base. We have chosen to sacrifice a small amount of our original target fuel efficiency in order to reduce the size, weight and cost of the recuperator which means that our initial fuel efficiency target will not be met - but we will be fairly close.

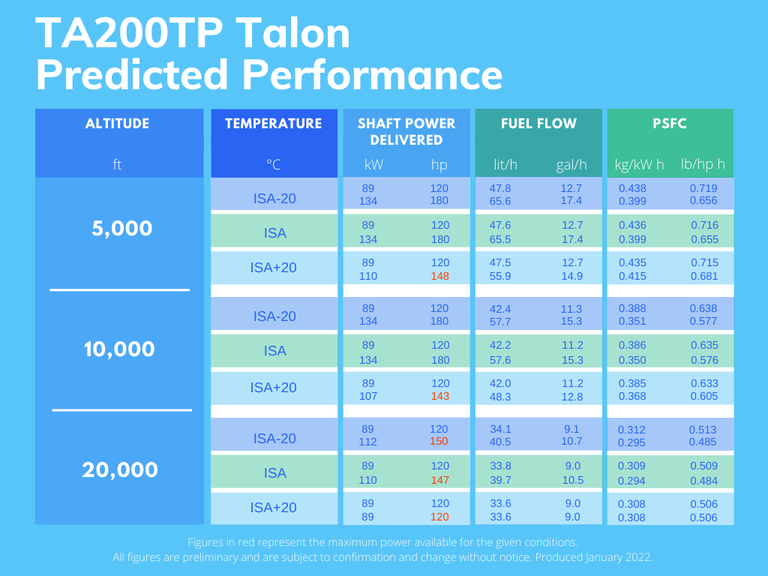

The following table details the predicted performance of our Talon engine, as the design stands today. We have selected 120hp and 180hp as indicative cruise powers to demonstrate indicative PSFCs and fuel flows. Please note that at ISA conditions, the power available from the Talon is 200hp up to 8,000’ with maximum power at 10,000’ and ISA conditions being around 187hp.

We expect the figures in the table will change slightly as the design evolves from the prototype engine into the production engine. When looking at these figures and comparing them to piston engines, particularly the PSFC figures, please bear in mind that there is a density difference between JetA and Avgas fuels. It’s not valid to compare PSFCs when the density of the fuels used by the comparison engines are different (6.78 lbs/gal for JetA and 6.02 lbs/gal for Avgas), except where the density difference is factored into the comparison. What this means is that the PSFC for the JetA burning turbine can be 10% more than for the Avgas burning piston, but they will still be burning the same volume of fuel per hour.

Another point to note and this is not evident in the table is that the PSFC/fuel flows are not linear between 120hp and 180hp. The PSFC curve is actually fairly flat between 150-180hp so if you want to know what the fuel flow is at 150hp, the PSFC will be closer to the 180hp figure than to the 120hp figure.

Once we have tested the engine, we will provide graphs where actual and accurate fuel consumption figures can be obtained in order to assist customers to consider whether this is a powerplant that is desirable for use in their aircraft.

In the table below, the red figures are the hp limit (when maximum hp is less than 180hp) at that altitude and ISA temperature deviation.

If you have other questions about the engine, please submit them to us directly via the button below or visit our forum to see if they have been answered there!