When a turboprop powered aircraft lands at any airport, all heads turn!

20 October 2022

While you might be comfortable with your current piston engine, have you really considered what a turboprop might do for you?

There are the obvious benefits including increased reliability, far fewer moving parts, no pistons, no lifters, no cam, no connecting rods, no spark plugs, no magnetos. You get the picture. Virtually vibration free.

Changing over to a turboprop should be a straightforward process and here are some good reasons why you might want to consider it.

Safety

Reliability and safety are generally far superior in a turboprop. There are fewer moving parts, and consequently, less failure modes. This is particularly important when you are flying over mountainous areas or large bodies of water, especially at night! The chances of finding yourself in the situation of needing to land quickly should be considerably lower with a turboprop, so you can feel more relaxed as you take in the sights. Check out this Twin & Turbine article from January 2020 that states "turbine engines have a failure rate of one per 375,000 flight hours compared to one every 3,200 flight hours for piston engines."

Fuel

You may have heard that turboprop engines are fuel hogs, burning much more fuel per hour than their piston counterparts, but we are working towards including recuperator technology in our engines, which means fuel burn in cruise should be very comparable to that of piston engines with equal power.

There are no lead emissions from a turboprop. Turboprops can also run on cheaper fuel that is more readily available in many parts of the world like JetA or kerosene-based fuels, so it is not just limited to running on AVGAS.

TBO

Consider the time between overhaul (TBO). We’ve all been there, watching the Hobbs as it ticks closer to that magic number and suddenly, it’s time to overhaul. For a turboprop the TBO is generally longer. Our engines have a target TBO of 3,000 hours (to be confirmed) as opposed to the 2,000 for most piston aircraft engines. This represents a 50% increase, which should reduce downtime and overall lifecycle expense. That means a lot more time spent enjoying your aircraft and a lot less time (and money) spent overhauling!

Simpler Operation

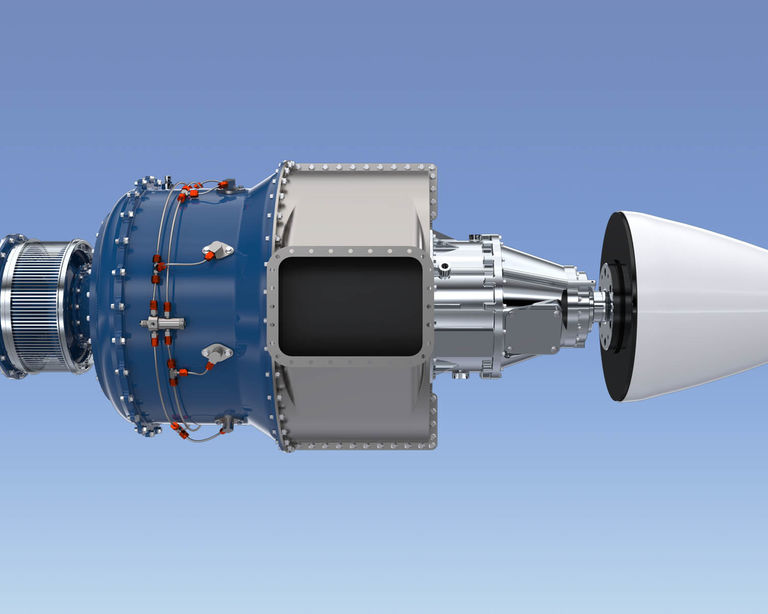

Generally speaking (and what we're working towards), a turboprop engine is much simpler to operate than a piston. This is due to the single lever operation capability of the engine. There is no mixture control needed on a turboprop, and TurbAero engines will be set up so that the prop is automatically controlled without pilot input. This will be accomplished by our integrated Power Control Unit (PCU), which controls both the engine and the propeller. The PCU also provides automatic overspeed protection for both the N1 and N2 sections, as well as automatic protection from over-temperatures and over/underpressures.

In turboprops, pilots no longer have to monitor Cylinder Head Temperatures (CHTs), as there are no cylinders. Exhaust Gas Temperatures (EGTs) are no longer an issue as manual fuel/air leaning is eliminated.

TurbAero engines will have an integral starter generator attached to the gas generator shaft and the start sequence will be fully automated, i.e. turn on the engine master, press the start button and wait for the engine to stabilize at idle.

Our engine is being designed to interface with a popular suite of avionics with plug and play wiring looms being in the pipeline to simplify the installation process.

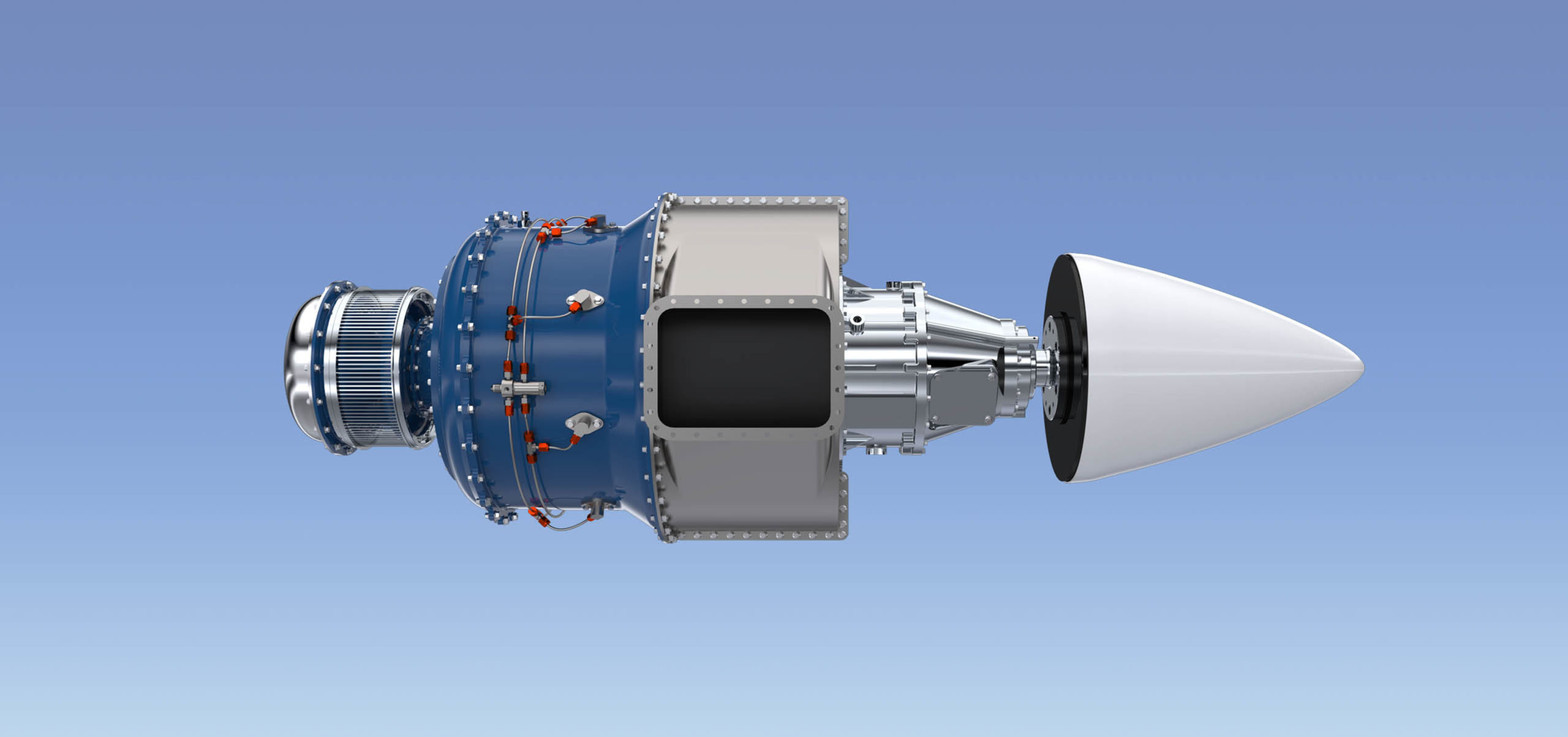

Weight and Size

Turboprop engines are typically lighter in weight than equally powered piston engines. This advantage can translate to more payload capability for the turboprop equipped aircraft.

Turboprop engines are also typically narrower and a bit longer than equally powered piston engines. As such, cowls on turboprop powered aircraft can be more aerodynamically shaped, thereby reducing drag and increasing speed for the same power (enhanced fuel efficiency and top end speed).

These are some of the tangible benefits, but what about those intangible ones?

Coolness Factor

Fly higher where it is cooler in the summer and the air is less dense, potentially affording you faster speeds and less traffic. Also, what about being waaaay cooler looking with that aerodynamic shaped cowl!

When a turboprop powered aircraft lands at any airport, all heads turn to see what it is…the sound is powerful, distinct, and of course, awesome!

Our Mission

At TurbAero we began the development of our family of turboprop engines with three main goals in mind, design and build a turboprop engine that would:

- sell for a price that would make it competitive with piston engines of similar horsepower

- offer a fuel burn comparable to piston engines of similar horsepower

- offer maintenance costs comparable to, or less than piston engines of similar horsepower.

We believe that we are on track to accomplish all three goals.

We plan to have firewall forward packages developed and offered for many of the more popular experimental (homebuilt) models, making the retrofit of our engines easy.

We're currently taking registrations of interest to purchase an engine when we open the order book. To register your no-obligation, no-cost interest or to find out more information, please click on the button below.

Further Resources

There are other resources online that you can use to learn more about changing over to a turboprop. Check out this chapter from the Airplane Flying Handbook produced by the US Department of Transportation Federal Aviation Administration for further information: ‘Transition to Turbopropeller-Powered Airplanes’.

If you enjoyed this article, you might like to check out the 4 stages of developing a turboprop engine, 5 main things to consider when converting your aircraft to a turboprop or will a TurbAero turboprop fit in my aircraft?