Progress in our technical program has been pleasing and it is exciting to see prototyped parts starting to arrive!

The design work continues, with a great deal of effort being applied to the process by our engineering team and our design and manufacturing partners. We are pleased to welcome a new engineer onto our team who will be working on our FADEC and Power Electronic components. It will be good to see these elements of the engine progressing faster, now that the design efforts have been substantially brought in-house.

The design of the aerothermal components has reached the stage where we need accurate performance data for our recuperator before the design of these components can be finalized, such that we can get the components prototyped.

Recuperator

One of the differentiating technical elements of our engine is the recuperator. The major drawback associated with incorporating recuperator technology into our engine is that it makes the design process significantly more difficult. The recuperator affects both upstream and downstream components. A small change in recuperator performance will affect the performance of other critical components. Consequently, we need to ensure that the recuperator is accurately characterized for both design point and off-design operations, before we can complete the final design of the remaining components.

Having designed many versions of the recuperator, analyzed those and tested some, we are now in the process of analyzing what we hope to be the final iteration. We shall be testing this latest iteration over the coming months with the expectation that this will be our conforming unit. If it passes its structural and performance testing, we will compare the data derived from testing to the theoretical data for the component to generate a correlation between the two. This will enable us to complete the final design of the aerothermal components and proceed to full engine prototyping.

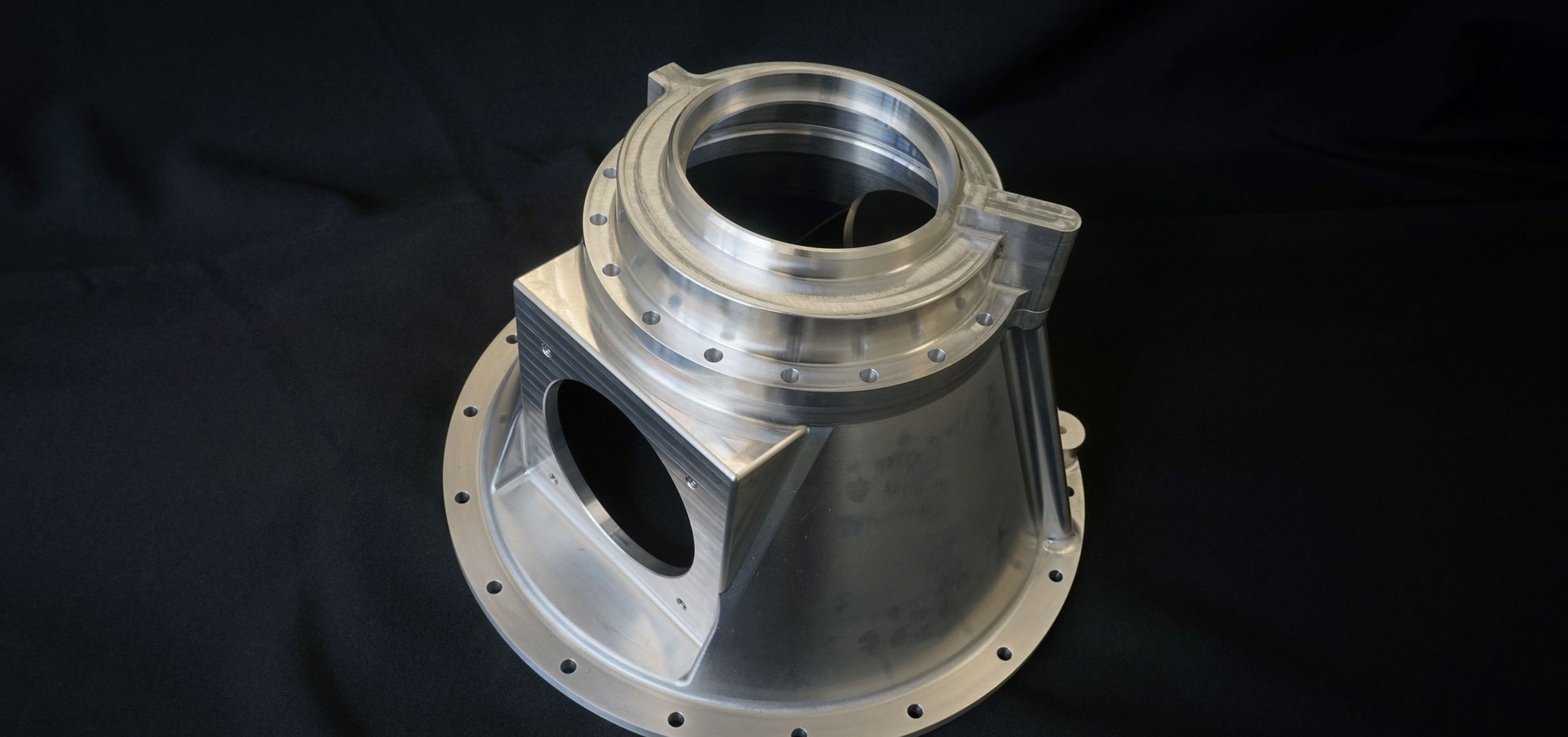

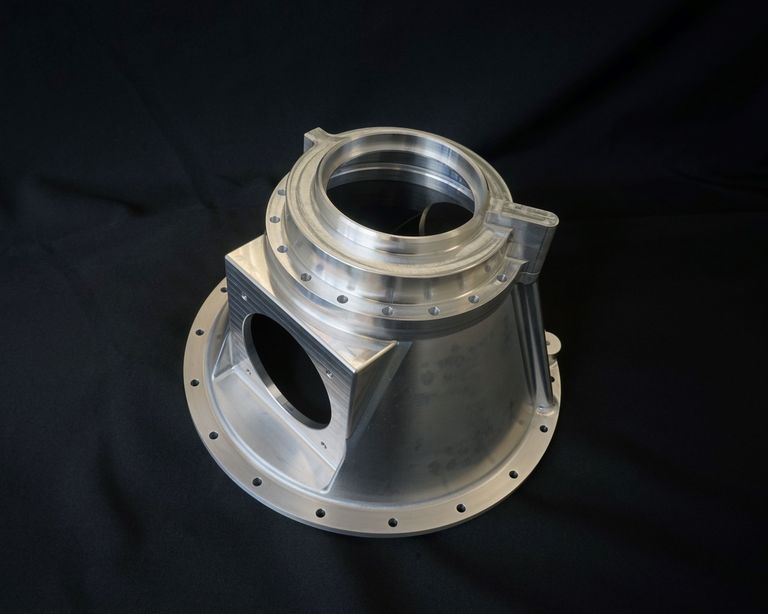

Prototyped Components

We recently received the delivery of the major static and rotating components for the gearbox. We are currently sourcing the remaining off-the-shelf components (bearings, seals, nuts & bolts etc.), before we undertake assembly and testing of the gearbox which will occur at our Australian workshop. While it was exciting to see components arrive, it will be more exciting to see those components going together to become the actual gearbox.

Other major activities underway are the design of the starter/generator, the FADEC, with tweaking of the secondary air system and compressor/turbines/combustor to be done, following the recuperator characterization.

Subscribe to our updates using the button below to stay up to date.