Design and technical program progress

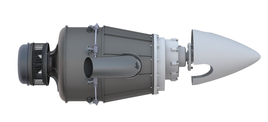

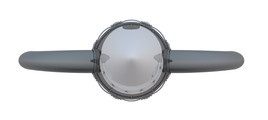

Our key focus for calendar Q4, 2019 and Q1, 2020 continued to be completing the detailed design of the launch engine. We are very pleased to be extremely close to achieving that milestone. The latest rendering of the CAD model is shown below fitted with a 12” spinner to give an indication of size.

Some small changes to a few components that were suggested by our manufacturing partners necessitated some changes in other components. However, the iterative process required to complete the overall design for the engine is now restricted to very minor changes. Once these are completed, we should have an engine that will not only achieve the highest level of efficiency and reliability as possible but should also ensure the cost-effective manufacturability of the engine.

The design or sourcing of the ancillary equipment associated with the engine (such as the starter/generator, engine control unit, etc) is well advanced, and it is anticipated that these tasks will be completed during early Q2, 2020.

Other key elements of the final design and prototyping process include:

- Our gearbox design team has completed the detailed design of the gearbox and prototyping of that assembly will shortly commence. This will be followed by standalone testing of that assembly.

- The starter-generator design is close to finalisation and will offer a generator with a 24v/100a capability. The starter element of this unit will have the capability to not only

- start the engine that is fitted with conventional roller element bearings but will also have the capability to meet the demanding requirements to start the next engine variant which will use foil-air bearings.

- The design of our custom fuel pump is well advanced. Our pump has been designed with certification in mind and has some rather nifty electronic capability built into it including a health monitoring system. This ‘top of the line’

- pump will warn of an impending failure which is a significant safety feature. We intend to offer a dual fuel pump option to enhance safety through redundancy.

- We are working with an experienced supplier to customise an Electronic Control Unit (FADEC type) for engine control. Again, a dual independent FADEC system will be offered to enhance safety.

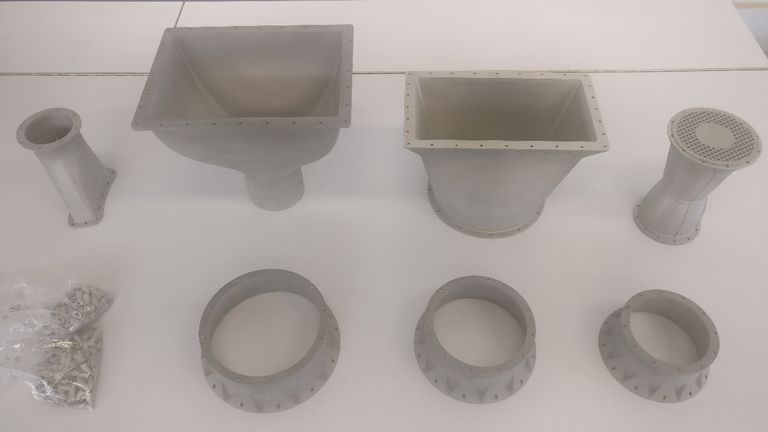

- We have prototyped three recuperator test pieces in preparation for functional testing. In addition, a recuperator test rig has been designed by our engineering team and individual components for the apparatus have been fabricated.

On the topic of the recuperator, over the next few weeks, the recuperator test rig components will be assembled by our engineers and recuperator testing will be undertaken. The three prototype recuperator test pieces that have been fabricated will undergo rigorous testing to evaluate both performance and structural integrity. The results from this testing will enable the engineers to determine a baseline correlation between theoretical and practical performance for each of the recuperator configurations, thereby facilitating the ability to complete the selection of the preferred recuperator configuration and to complete the final design for the prototype engine.

For those with a technical interest, the following photo shows some of the individual components of the recuperator test rig.

Work continues on our Arion Lightning test aircraft to prepare it for the integration of our turboprop engine, once the requisite ground-based testing is completed on the engine.

For our flight test program, we are fortunate to have the support of a highly skilled and respected ex-Royal Air Force test pilot and keen experimental aircraft enthusiast who will be planning and conducting the flight test schedule for the airframe/engine. He has also offered to provide complex data acquisition equipment from his flight test business to be fitted to the aircraft to give the highest level of integrity to the data obtained during the flight test program. He will be ably supported by an Adelaide based ex-RAAF test pilot who is also an avid experimental aircraft enthusiast.

Check out our engine here or subscribe for updates below to be among the first to hear about the progress we are making at TurbAero.