The progress in our technical program has been both pleasing and frustrating at the same time. The pleasing aspect is that we have made significant advances in our design and prototyping programs, however, several components have been redesigned after input from the manufacturers, and prior to undertaking prototyping, which has delayed the prototyping of those components.

We are also experiencing other challenges with the prototyping process. The prototyping of several key components has been delayed due to supply chain issues. The ability to source the very specific materials has proven to be challenging - even for fabricators who do this on a daily basis. A specific grade of aluminum for the gearbox casing or a special grade of metal for rotating components for example have been difficult to source. We have also been insistent on having sample materials analyzed to ensure that the material meets our strict quality standards.

While the delays are frustrating, we recognize that such delays are typical in a complex technical program and will ultimately result a safer, more reliable and more economical engine for our customers.

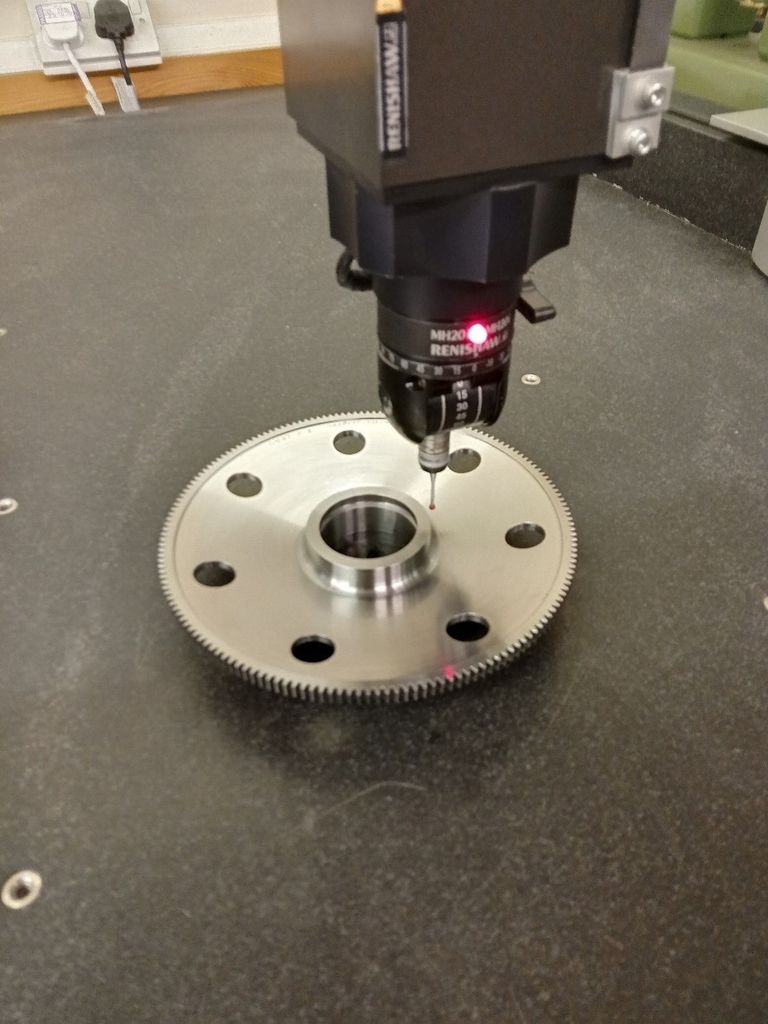

- Pictured above is one of the cogs for our two-stage planetary gearbox that is currently being fabricated. The process of taking a billet chunk of material and watching it transformed into a piece of precision machinery is fascinating. Ensuring a quality check of the component is completed after machining is an important element of the fabrication process. Dimensional accuracy is critical, as is the accuracy of the material properties of the stock from which the component has been made.

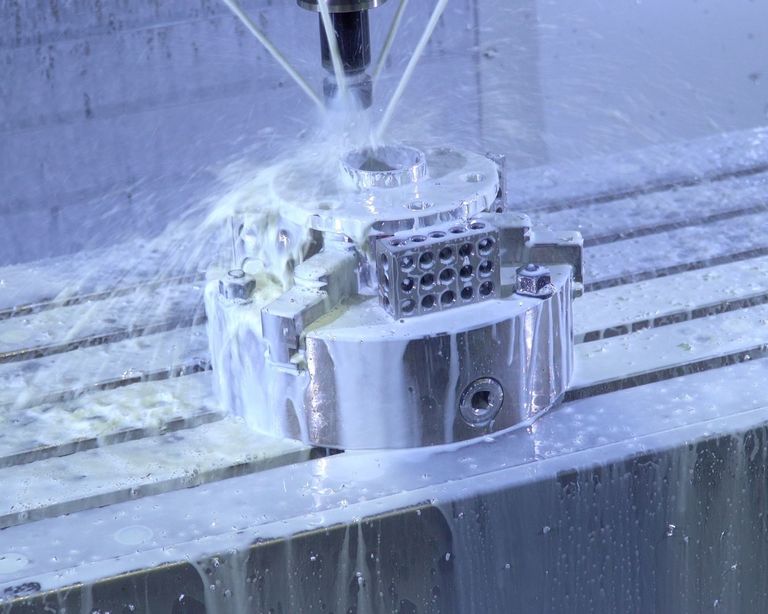

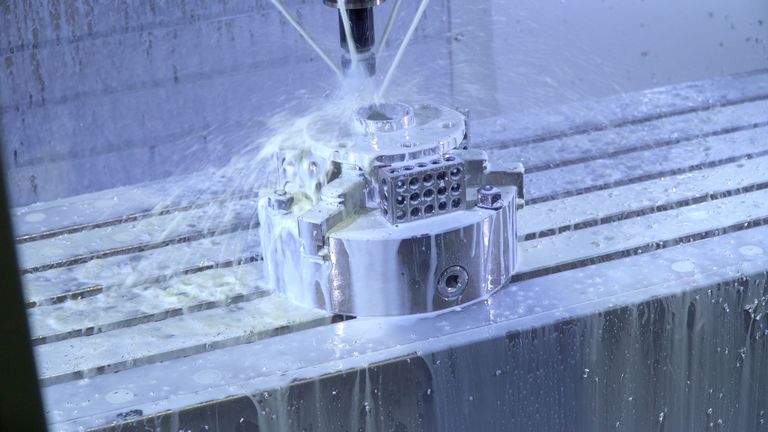

One assembly where it has been amazing to see the progress being made, is in the fabrication of components for our gearbox. The gearbox is one of the most complicated assemblies on the engine, from the perspective of potential failure modes, the precision requirements for individual components, and from the rotor dynamic perspective, due to the multitude of rotating gears and shafts. We are on track to have it on the test stand during the next quarter where it will undergo rigorous testing prior to being installed on the prototype engine.

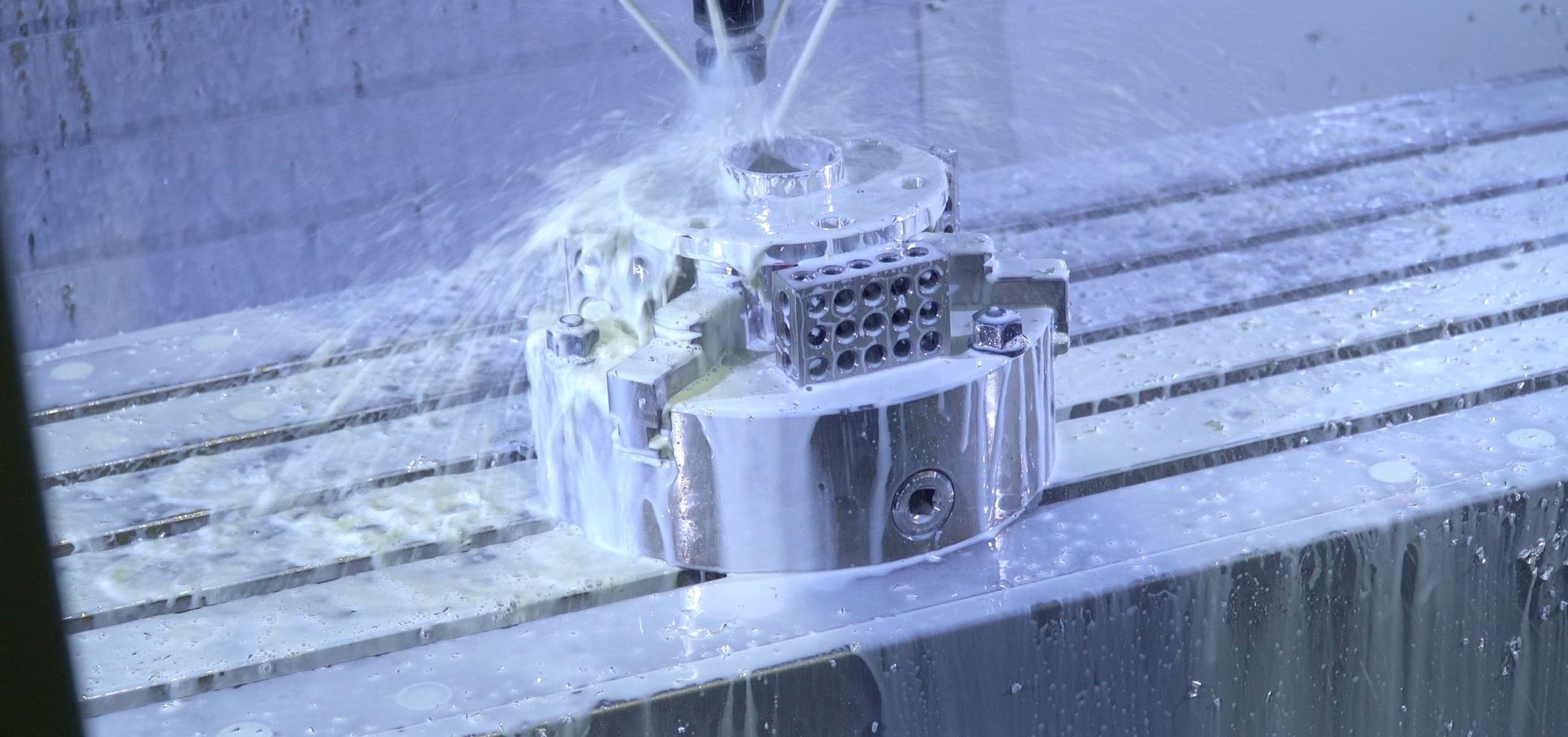

- Propellor flange element of the gearbox being machined.

Of course, our technical program is not complete without the road bumps that we experience along the way. The road bump for us in the last quarter has been around the shaft to turbine attachments. There are several methods traditionally used to attach turbines to shafts. Our preferred method, from the perspective of assembly and cost, comes with the requirement for significant testing. In order to reduce the amount of testing and to de-risk the first engine run, we have chosen to adopt an alternative attachment method to the preferred one. This will allow us to get the Talon on to the test stand with less individual component testing, in a shorter timeframe and with less risk. The downside to this solution is that the prototyping of these shaft and turbine components has been delayed. Of course, we shall continue to pursue the preferred design for the shaft and turbine attachments, with its associated testing, in parallel to assembling the test engine, to ensure that the production Talon engine will be the optimum final product.

We are also pleased to be progressing in the area of the design and preparation for prototyping of several of the accessory components. These include a custom starter-generator for the engine, where components are about to be ordered to commence assembly of the first unit. Similarly, the design of customized fuel pumps continues to make positive progress with fabrication of the prototype about to commence. The fuel pumps are technically challenging due to the low fuel flows but high-pressure requirements. Cooling of such pumps is one of those challenges that must be overcome but we are confident that we have the final configuration for this component.

Subscribe to our updates using the button below to stay up to date.