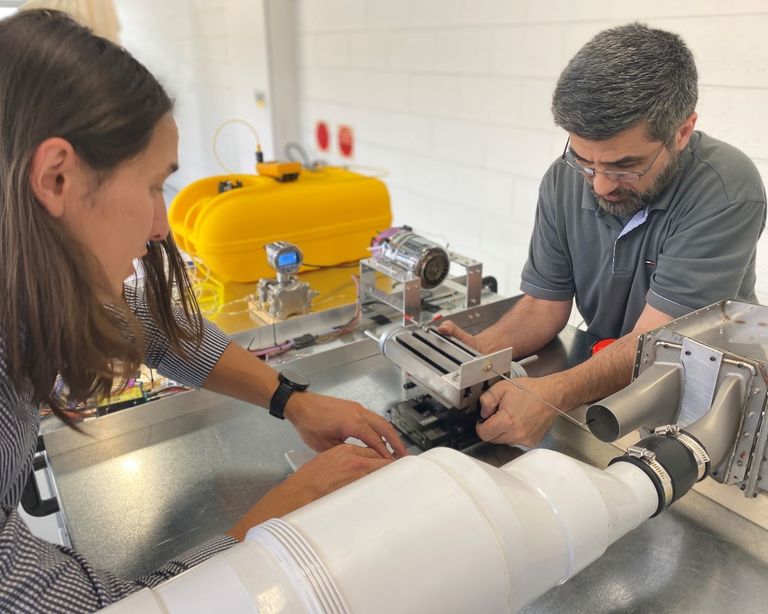

On the technical front, we’ve made great progress. The secret sauce to achieving our target fuel efficiency is the recuperator component of our engine. Using our in-house developed proprietary CEGETM technology, we believe that we have reached a compromise on effectiveness, weight, size and cost that will offer appealing fuel efficiency at the right price point. Attaining this result has been exceedingly challenging and we anticipate validation of our theoretical design during the next quarter when we will undertake laboratory testing of the latest iteration of our CEGETM heat exchange technology. We anticipate that this latest iteration will be our production component.

During the last quarter, we have undertaken the design of a two-stage epicyclic gearbox. This will be available as an alternative to the parallel shaft offset gearbox that we have already developed which will be on the model to be displayed at Oshkosh. The benefits of the epicyclic gearbox are that it is significantly more compact and lighter than the offset gearbox to the tune of between 20-25 lbs (10-15kgs), which is substantial.

One element of the epicyclic gearbox design is the provision for a prop governor to be mounted on the gearbox in order to facilitate the use of a hydraulic constant speed propeller. Although designing the engine/gearbox to use an electric propeller would simplify the engine design and reduce cost, we chose to design the capability into the gearbox to offer flexibility on propeller types. What props we ultimately recommend for use on the engine will be determined through both ground and flight testing.

Our engine control unit is currently being customised to be a perfect match to our engine, in order to ensure the stability of the engine in all areas of the start, ground and flight envelopes.

The fuel and oil systems have been fully specified with all components of these systems having been sourced. We will commence the purchase of these components very soon.

Know someone in the aviation component manufacturing industry?

We are currently sourcing suppliers for all components, both for the prototype engines and also for our production engines. We understand that several TurbAero community members are involved in the aviation component manufacturing industry, or know of someone who works in this industry.

While we already have a comprehensive list of potential suppliers, we would hate to miss a quality supplier simply because we didn’t know about them. As such, we would love to hear from people that have, or know of, a shop that could provide quality aerospace-grade turbine engine components. Please email or connect with us via our Contact Us page. We would be grateful for your feedback or connection to these companies.

Want to stay ahead of the POWER curve?

Make sure you're following us on our socials: Facebook and YouTube

And make sure you stay ahead of the POWER curve by subscribing to our updates using the button below.